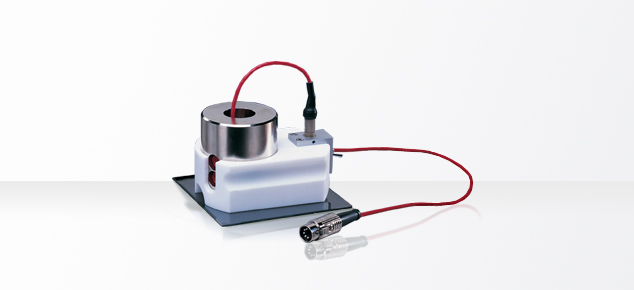

A four-point resistivity probe that can be hand-held and applied, incorporating a Jandel cylindrical probe head.

Principle Features

- Teflon body

- 4-point cylindrical probe head can be easily changed

- shorting switch to prevent sparking

- easy placement by hand

Application

- Measurement of bulk resistivity of large ingots unable to be mounted on a normal probe station.

- Measurement of sheet resistivity of very large wafers or deposited films on large substrates.

General Description

The unit comprises a Teflon body containing a cylindrical brass mass sufficient to cause the probe needles of the 4-point head (loaded up to 200g each) to be completely retracted. The Teflon body incorporates a lead about 1m long to connect to the associated electronic measuring equipment. There is a toggle switch marked ‘S’ (shorted) and ‘R’ (read) which permits the probe head to be raised off the sample, or placed on it, with no sparking. The current source is shorted at position ‘S’ on the hand applied probe independent of the FWD, SBY, REV switch on the power supply. Of course, when the probe head is in position the FWD/REV positions can be used in the usual way to observe forward and reverse readings.

Operation

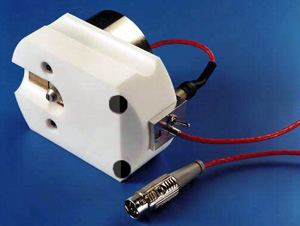

The probe head should be installed so that its acrylic insulating pad (adjacent to the projecting probe needles) lies in the same plane as the lower Teflon surface. Rotate the probe head so that its needles lie at right angles to the longitudinal axis of the Teflon holder, and clamp firmly with the two red screws. To present the probe head to the specimen it is best to make contact with the rear end of the block (where the switch is) and rock the block downwards so that it effectively pivots about the rear. In this way the probe points will retract without scrubbing on the specimen surface. The actual position of the probe points can be seen via the cutaway.

High Temperature Option

The Jandel Hand Applied Probe is available in a version that can withstand temperature of up to 200oC in an oven. The “read/standby” switch is removed and the Cylindrical Probe Head is modified to withstand 200oC.

A complete four point probing system consists of the Hand Applied Probe shown above, combined with either the RM3 Test Unit or the HM20 Hand Held Meter.

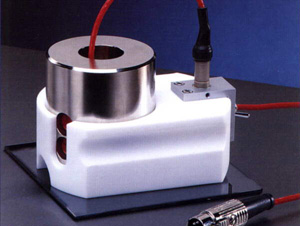

Bottom View – Click photo to see larger image |

“In Use” View – Click photo to see larger image |

Specifications:

| Dimensions: | Length: | approximately 125 mm (4.9″) front to rear |

| Width: | 75 mm (3″) | |

| Height: | approximately 80 mm (3.15″). The wire from probe head projects an additional 30mm (1.18″) upwards | |

| Weight: | approximately 1.6kg (3.5 lbs) | |

| Downward force: | approximately 1.1 Kg (2.4 lbs) – sufficient to easily retract 4 needles with 200g load | |

| Material: | Virgin Teflon body with nickel plated brass weight to accept Jandel cylindrical probe Ø 25.4mm | |

| Electrical: | 4-point probe with Teflon screened lead and Lemo 5-way plug and socket. Toggle shorting switch. Teflon screened lead to 180 degree x 5-way DIN plug. | |

Downloads

System Configurations

| Hand Applied Probe with RM3000 Test Unit | |

| Hand Applied Probe with HM21 Hand Held Meter |

Four-Point-Probes is a division of Bridge Technology. To request further information please call Bridge Technology at (480) 219-9007 or send e-mail to Joshua Bridge at: sales@bridgetec.com